ERS with Lindsey

The leading choice of utilities around the world, Lindsey Emergency Restoration System (ERS) structures are designed to rapidly bypass permanent transmission towers at any voltage in any terrain. Lindsey ERS can be erected in hours and are suitable for hand, crane, and helicopter installation methods.

Though designed for temporary use, many utilities have kept Lindsey towers in continuous service for over a decade and counting because of their robust design.

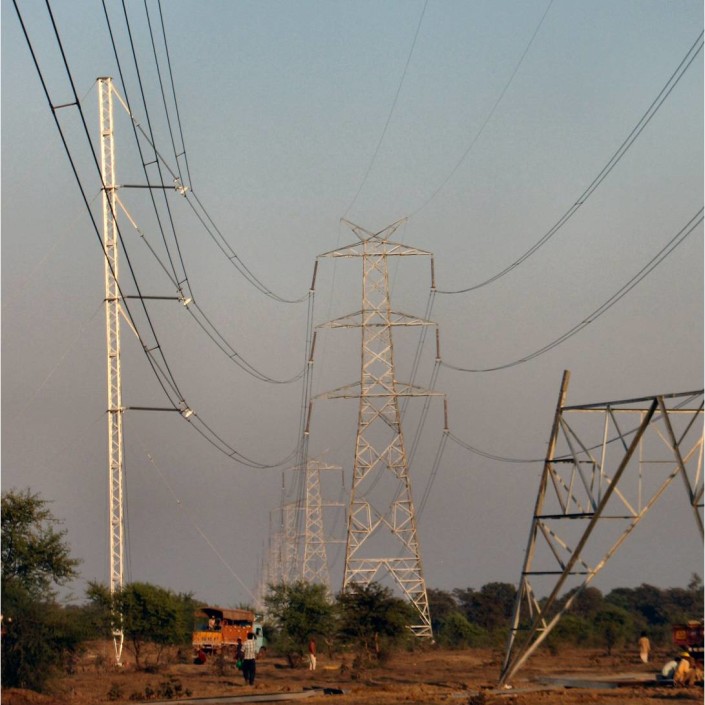

Terrain Conquered

Lindsey ERS structures support mountain-to-mountain spans in the Himalayas, EHV lines crossing the hot, hard-packed sands of the Middle East, and in the soft-soiled flood plains and estuaries of Southeast Asia.

Flat, hilly, or mountainous terrain? Loose, rocky, hard-packed or marshy soils? Lindsey’s ERS engineering team can work with you to determine the best gimbaled structure design, and the most appropriate foundation bases, anchor types and installation methods for your system. Have the confidence that Lindsey ERS can conquer your terrain.

An Essential Part of Grid Resiliency

Damage is Always Unplanned

Storms, soil erosion, ice, earthquakes, flooding and willful acts all can damage or destroy towers. Lightweight Lindsey ERS structures are designed to rapidly get lines back in service. By quickly and safely bypassing damaged permanent structures, ERS structures allow you to rebuild or replace the permanent structures without time constraints.

Support during Construction and Maintenance

Lindsey ERS structures have been used to bypass transmission lines around towers or entire substations that are under construction or being maintained, replaced, or expanded.

Why LINDSEY ERS?

Lindsey ERS structures have been the leading choice of utilities for decades to provide for unscheduled tower restoration and scheduled construction.

Versatility is our Hallmark

Lindsey ERS structures are completely modular and reusable. All system components can be used to configure dead-end, running angle, tangent, herringbone, and chainette structures. Requiring no special foundation, suitable for any soil, and capable for use at any voltage, AC or DC, Lindsey ERS structures provide the ultimate in flexibility.

Lineman Safe and Lineman Friendly

Lineman safety and convenience are built in to every Lindsey ERS. Compatible with all commercially-available fall arrest systems, linemen feel safe using familiar gear. Wide, comfortable footing means confident climbing, supporting as many as 4 workers at the same level. A variety of platforms, lifts, hoists, and other accessories simplify and speed installation. Lindsey ERS structures use only permanent anchors for safety during construction.

Four LINDSEY Models

ERS Comparison Table

ERS Models

If you're looking for

Relative Buckling Strength

Column Section Weight

Fall Arrest System

Standards Compliance

Flat Climbing Surfaces

Installation

Construction

Stores in 20' Containers

600L-Series

High-strength, lightest-weight components for hand transport, and compact storage

100%

80kg

(2.9m)

Universal

IEEE Std 1070 Design and Testing; IEC 60652

Yes

Manual, Crane, Helicopter

All extruded or plate aluminum construction

Yes

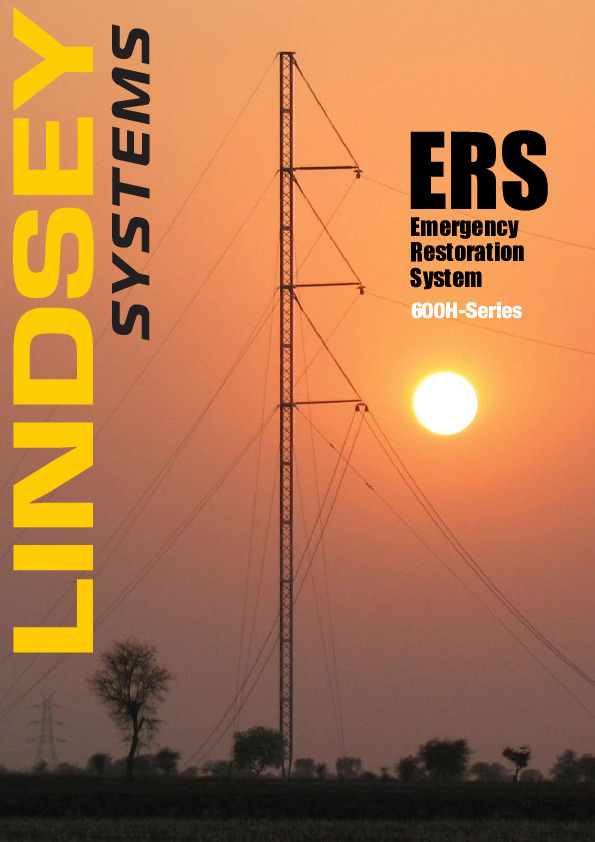

600H- Series

Very high strength and compact storage

130%

95kg

(2.9m)

Universal

IEEE Std 1070 Design and Testing; IEC 60652

Yes

Manual, Crane, Helicopter

All extruded or plate aluminum construction

Yes

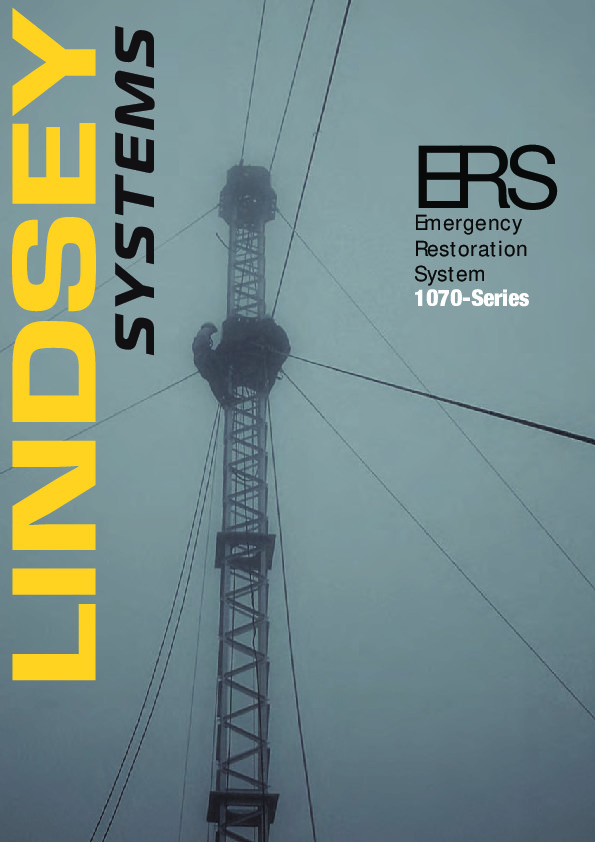

1070-Series

Very high strength and full compliance to IEEE Std. 1070

150%

188kg

(4.3m)

Universal

IEEE Std 1070 Design, Testing and Dimensions; IEC 60652

Yes

Manual, Crane, Helicopter

All extruded or plate aluminum construction

Yes for all except column sections

800-Series

Extremely high strength, optional hands- free helicopter assembly, compact storage

300%

144kg

(2.8m)

Universal

IEEE Std 1070 Design and Testing; IEC 60652

Yes

Manual, Crane, Helicopter installation, and Helicopter assembly

All extruded or plate aluminum construction

Yes

Non- Lindsey

See full table

70%

125-135kg

(2.6 - 2.8m)

Proprietary and not compatible with all

Varies

No

Manual, Crane, Helicopter

Varies

Yes

Construction Methods

Lindsey ERS structures have been designed by engineers that have been installing ERS in the worst locations around the globe for over 30 years. Manual Installation, on the ground, and in the air, we can do it in every situation.

LEARN MOREReliability and Safety

- Design and proof tested to IEEE Standard 1070-2006, the only world-wide accepted standard for ERS. Lindsey 1070-series ERS are also fully compliant with the dimensional requirements of this standard.

- Testing performed in accordance with IEC-60652 “Loading Tests on Overhead Line Structures.”

- Lindsey is ISO-9001:2015 Certified for Design and Manufacture of ERS

- Lindsey is ISO-14001:2015 Certified for our Environmental Management System

Nobody trains better than Lindsey

Nothing replaces training on your equipment in your locale. Lindsey training programs are led by ERS engineers with deep application knowledge and years of experience. Lindsey will train at a central training facility, or even in the field on an actual job site. Your equipment. Hands on. Knowledge gained.

LEARN MOREVideo Testimonials

ERS Resources

White Papers

Extreme Weather and Transmission Tower Collapse

Planning Ahead Proves Invaluable to Restoration of Pacific DC Intertie

Planning and Training Reduce Restoration Time in India

Experience Restoring Damaged Lines in the Philippines

Transmission Line Restoration in Colombia

Controlling the Economic Risk of Line Failure